Once the morning sessions at the Flax and Linen Symposium were over, and had obviously been successful, I moved into the afternoon mode. I have already posted photos of the demo session in the afternoon. I didn’t post this photo at first because it seemed too frivolous. However, I decided to include it because you can obviously see that I am happy. Goofy and happy. As nervous as I was and as much as my legs were shaking, it was fun. So, here’s a photo of me having fun amidst the anxiety:

The bemused person standing next to me is the lovely Jill Horton Lyons of Winterberry Farm in Colrain, MA. I continued to be nervous all the way until Saturday evening, however.

I was in charge of organizing and facilitating the last panel on Saturday afternoon, called “Flax Today”. After the demonstration session down at the History Workshop, everyone headed back to the Deerfield Community Center (where the majority of the symposium was held). We were all quite happy that they had installed air conditioning earlier in the summer, since it turned out to be a very hot day. Here’s a view of the room as we were gathering:

Here are some of the presenters sitting in the front row right before we got started:

My goal with this session was to highlight a range of contemporary, small-scale flax-growing projects and to explore some of the challenges facing a revitalized flax-to-linen industry in North America. Here are the presenters on the Flax Today panel, and a quick summary of what they talked about:

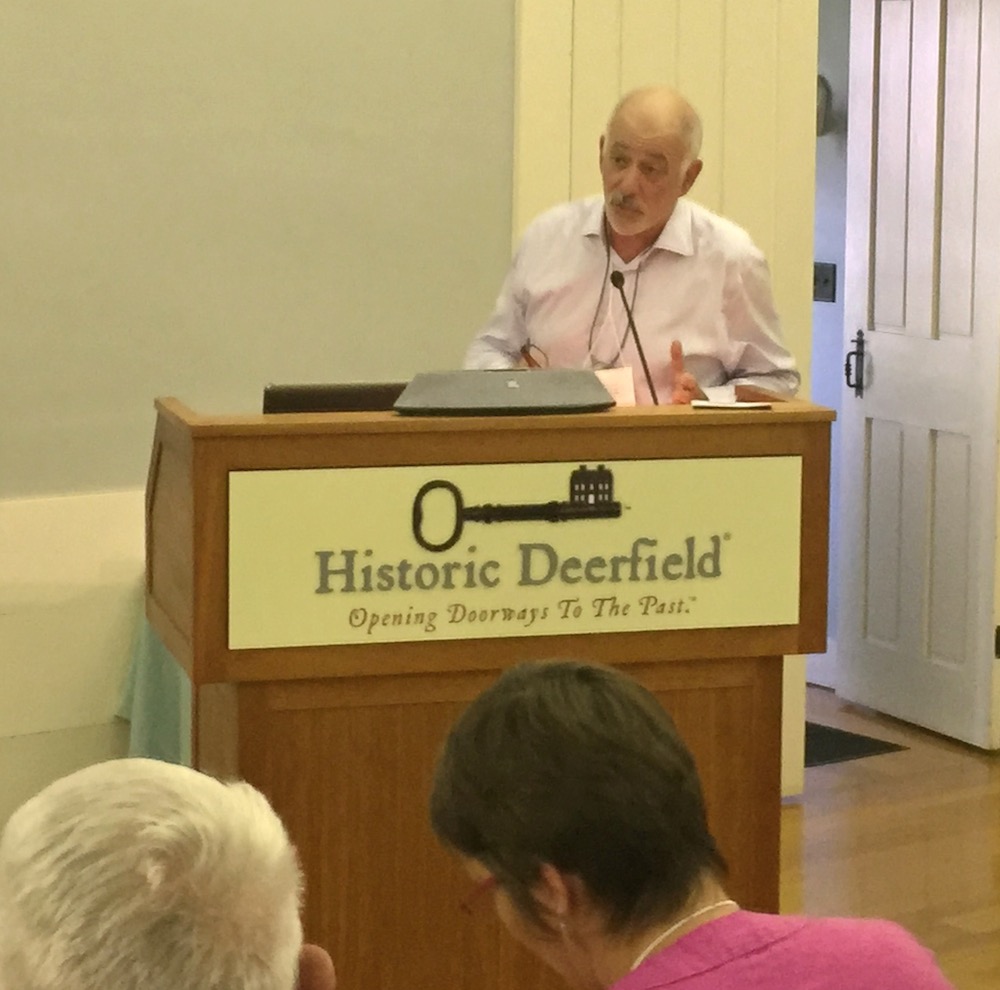

Jeff Silberman is chair of the Textile Development and Marketing department in the Jay and Patty Baker School of Business and Technology at FIT. In this session, he was speaking about the current realities of natural fibers in the global textile market, and flax in particular. Linen is currently a teeny niche which is facing a formidable competitor in hemp, which he illustrated graphically as an almost-invisible sliver on a large textile pie-chart.

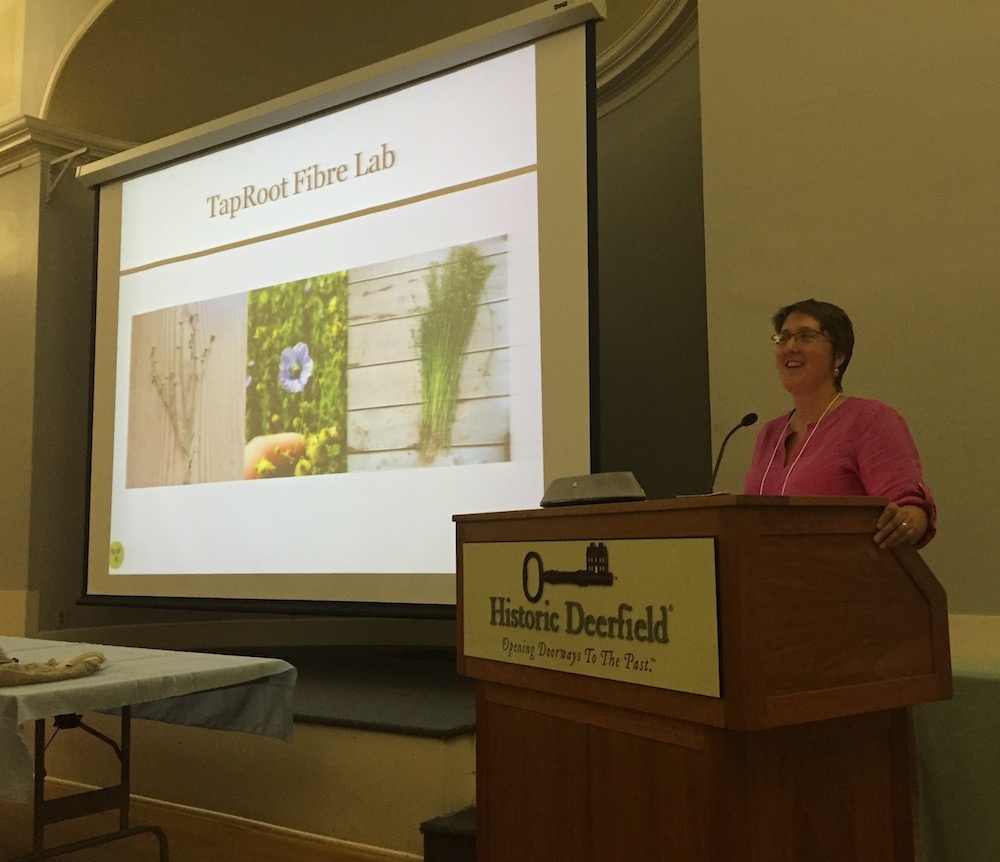

Patricia Bishop is an owner and farmer at TapRoot Farms and TapRoot FibreLab in Nova Scotia. TapRoot Fibre Lab is designing and producing a line of small-scale flax processing equipment. They are also acquiring spinning equipment to process both flax and locally grown wool into yarns with the goal of creating local cloth. Check out their blog here. (12/30/2023 Edited: Jeff has retired from FIT. Links to TapRoot Fibre Lab have been updated).

Each piece of flax processing equipment can function separately, or can be installed as a system that’s appropriate and affordable for local fiber/local economy initiatives. Patricia presented about the history and development of their flax growing project. She also screened video explaining the line of equipment they are creating. Engineer Mike Pickett was originally scheduled to come to the symposium and present this portion himself. However, as their production deadline loomed, he needed to stay in Nova Scotia and finish up the construction of the last machine. So, the video included never-before-seen footage of their newest equipment in operation! I was so excited and felt so lucky to be in attendance for the North America debut of this video (which you can watch on You Tube here).

Sandy Fisher is a professional weaver and a founder of the Chico Cloth project in California. They are growing flax in arid conditions (including small patches in the shade in the winter-time) and processing it by hand with the goal of creating a uniquely local cloth. Retting under such arid conditions is a challenge! You can view some news articles about their project here and here. (12/30/2023 Edited: Chico Flax has a website now!)

Destiny Kinal of the Reinhabitory Institute, presenting on her research into small-scale technologies, growing, and processing models that could be adapted for a bioregional approach to local cloth. She is especially interested in sources of energy that are not dependent on fossil fuels, is enthusiastic about the possibilities of solar, water, and wind-powered mills.

Destiny’s observations about the labor and equipment used in pre-industrial times, and her speculations regarding the necessity of communal labor, made a great segue to the final talk on Saturday night.

For the keynote talk on Saturday evening, Christian and Johannes Zinzendorf presented their research about communal flax processing in the early Moravian community of Bethlehem, PA.

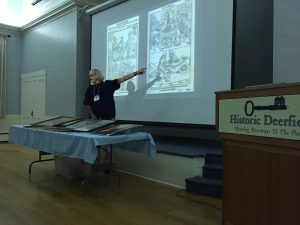

Here is Johannes explaining about the fate of religious non-conformist and reformer Jan Hus, who was burned at the stake in 1415 in Europe. The followers of Hus subsequently established the Unity of the Brethren, which become the Moravian church.

Early Moravian leader Nicolaus Zinzendorf believed that God entered directly into his heart, which you can catch a glimpse of in the illustration on the screen at the left of the photo:

The Moravians were avid missionaries who established outposts all over the world, which is how they wound up in Pennsylvania. Nicolaus Zinzendorf was one of the founding members of the Moravian community of Bethlehem, PA in the 1740s. In addition to explaining the history of Bethlehem, and the role of flax growing and processing in the town, the Zinzendorfs shared about their own personal journey and efforts to re-create an 18th century life-style. One major take-away for me was that two men, no matter how hard-working, creative, well-educated, and dedicated, cannot do the work of an entire community. They were inspiring nonetheless.