In my retrospective of the past 9 months, I somehow skipped over January. Oops! Here it is:

In January I had the pleasure of spending an afternoon learning how to make paper with May Babcock of Paperslurry. If you are interested in hand-made paper, especially paper from your own local plant material, then check out her website. She has lots of excellent, clear tutorials and links to fabulous resources and inspiring projects.

High quality linen paper is nothing new, though in the past it would have been made from linen rags. I don’t have a lot of old linen rags kicking around the apartment, but I do have a lot of tow!

Tow is the name for the shorter fibers in the flax process. The long fibers are called line. When you process flax, you end up with a lot of tow, and proportionately less line. Line is special, so small-scale growers such as myself reserve it for spinning a fine thread. Tow is good for spinning, too, but can also be used for many other things.

May had generously offered to help me make paper with my own flax tow. She walked me through all the steps, and in one afternoon we turned a handful of tow into several sturdy sheets of paper!

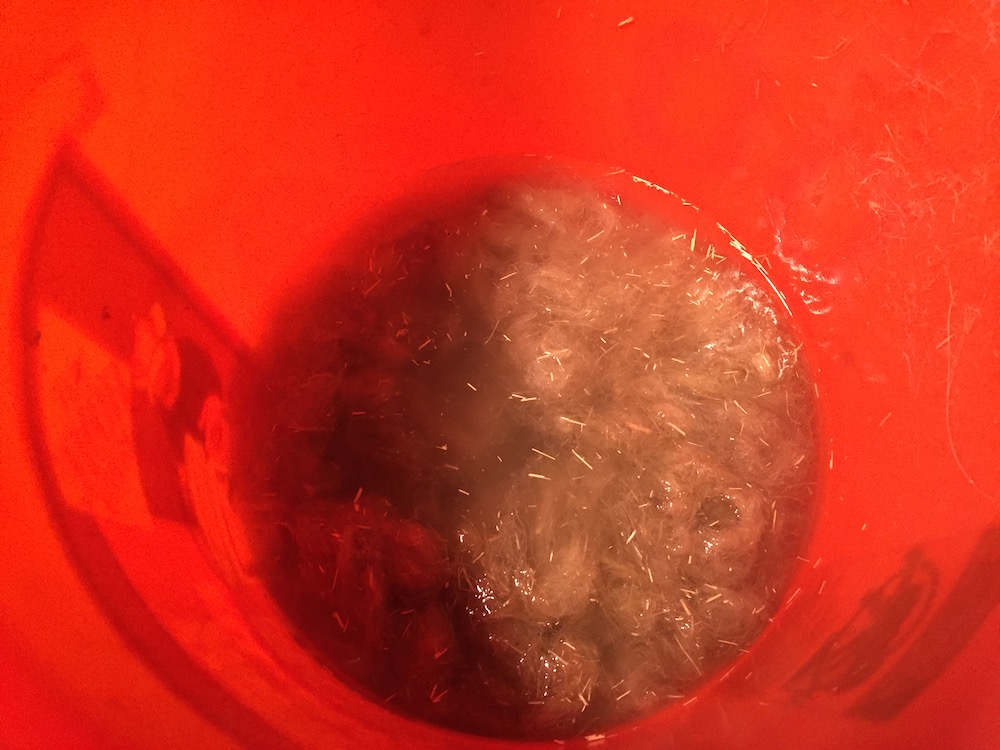

First, we weighed out 3 ounces of tow. We snipped up the fibers into short pieces, between a half and three quarters of an inch long. We dropped them into a 5 gallon bucket of water:

While we snipped, May explained that flax has several unique properties as a papermaking fiber. It expands more than other fibers when it’s wet, it’s stickier, and it shrinks more than other fibers when its drying, unless it’s constrained while it dries (i.e., is dried while attached to a physical backing and under a weight).

Then, May set up her adorable little Hollander beater.

The fibers go through a crushing, smooshing, beating process inside that gray cylinder in the center. Inside is a roller and a plate with teeth and grooves. The numbers taped up on the wall behind the beater are May’s guide for how many times she has to turn the mechanism that sets the plate and rollers at the height she wants. Raising and lowering the mechanism increases or decreases the pressure on the fibers.

In the beater, the fibers are compressed and squeezed, not chopped, so that they stretch out until they are very fine and create a lot of surface area. The fine strands are called fibrils.

Then she turned the Hollander beater on. It’s really loud!

Then we gradually added the wet, snipped-up pieces of tow.

Underneath the table is a bucket for catching drips.

The motor is powerful, but the fibers can get bunched up when they are first going through the beater. May monitored carefully and broke apart the clumps to keep things moving smoothly.

Here’s the beater running once we added all the tow.

Every 20 minutes or so, she scooped out some of the fibers, stirred them in a jar of water, and held it up to the light. This was to check how finely the fibers had been broken down. Then she adjusted the height of the plate. When things seemed right, we set the timer and let the beater run for an hour. Meanwhile we went to the back of her studio to look at some of her beautiful paper samples and talk about plants.

When the hour was up, May filled up a tub with water and wetted down the supplies we’d be using the make the sheets of paper. It being January, it was pretty cold, so we used warm water for comfort.

On the right of the tray are pieces of army blanket that we used as felts between the sheets of paper.

May added some of the flax pulp to the warm water.

Then she stirred it around until the ratio of water to pulp was right. This step is called hogging. Then our slurry was ready!

At this point I stopped taking photographs because my hands were wet. I got a chance to pull several sheets of paper using a beautifully crafted deckle and mould (12/31/2023 Edited: I corrected the spelling on those terms! And check out May’s resources page for equipment suppliers). I made two sheets with inclusions, which involves placing an item between two thin sheets of paper. I used a long strand of flax that May had grown, and some of my un-cut tow.

May explained that one of the properties of linen in papermaking is that it is “slow draining” so you don’t need to add anything to the slurry. Other fibers require a mucilaginous or viscous “forming agent” so that the water will drain through the screen at the right speed.

This is a stack of sheets of interfacing. I pressed the papers onto these, pre-dampened, as they came off the screen.

After I pulled a few sheets of paper, May put the stack of felts and interfacing into a small book-binding press and squeezed out a lot of the water.

After about 15 minutes, we took them out of the press. We peeled the strong, sticky sheets of paper off of the wet interfacing and placed them on dry sheets of interfacing and felt. We stacked them up between pieces of thick corrugated cardboard inside her drying rack. Then she put a heavy weight on top of the stack, turned on two fans behind the whole set-up, and left them to dry.

After the papers were dry, she mailed them to me. Here are three that were constrained while they dried so they are relatively flat and smooth:

Here’s a close up:

Here are the two sheets with inclusions:

This one was dried without constraints so it is more shrunken and wrinkly:

It reminds me of a motto that my Flax and Linen Study group considered at one point, “Wear your wrinkles with pride!” To make a linen textile smooth and shiny requires a lot of pressure and labor. To whit, starch and the mangle (an admittedly obscure but interesting and not straightforward topic in North America).

It reminds me of a motto that my Flax and Linen Study group considered at one point, “Wear your wrinkles with pride!” To make a linen textile smooth and shiny requires a lot of pressure and labor. To whit, starch and the mangle (an admittedly obscure but interesting and not straightforward topic in North America).

However, being smooth, supple, and shiny is only one of linen’s magical modes. The strength and beauty of linen reveals itself in so many other ways, including crinkly, shrunken, dry, and indestructible! Linen as crone.

There are tiny pieces of straw in my paper because I hadn’t carded and cleaned up the tow for spinning. More careful preparation of the fiber ahead of time would have led to a smoother texture, I think. That said, the papers are really strong!

It was an incredibly fun and inspiring day. I was excited to learn yet another way to use the amazing and versatile properties of flax, Linum usitatissimum: the most useful. Thank you, May Babcock!