Yesterday morning, Thursday May 3rd, I went for a walk around 7:15, as I often do, but little did I know that it would turn out to be an exceptionally inspiring walk (despite the drizzle).

First, as I came out of the little boggy wooded area behind our apartment complex into the parking lot of the JCA, I heard and saw two crows cawing away vigorously. At first I thought, two crows having a debate, or maybe just exchanging insults. Then I heard a third crow, which made me think that something a bit more interesting was going on. What are all those crows yelling about? And then, I saw something slip into the brambles and small trees by the little sunken wetland area in the center of the parking lot. I walked closer slowly, and looked carefully, and it was a fox! A gray fox, I think: very small, delicate, mostly beige, with a black back and not-very-fluffy tail. The instant that I stopped walking, turned my body, and fixed my attention on the fox, the crows stopped cawing. It was an intense moment, since I realized they had probably been shouting about the fox, and had stopped now that I had noticed it, too. I wished I knew what they were thinking. “Fox! Fox! Fox! Fox! Oh, look, a monkey. Let’s be quiet and see what the monkey does.” I watched the fox as it picked its way around the edge of the wetland area, through the bleached masses of dead cattails, and short new green growth. Maybe it was looking for frogs or other little creatures to eat, but it didn’t seem to find anything and kept on going. Then it climbed out the other side of the wetland area, trotted toward the edge of the building, and went around the corner out of sight. We see quite a lot of wildlife around here, but it was still a special treat to get to watch a fox for several minutes. I continued on my walk, and there was more excitement to come.

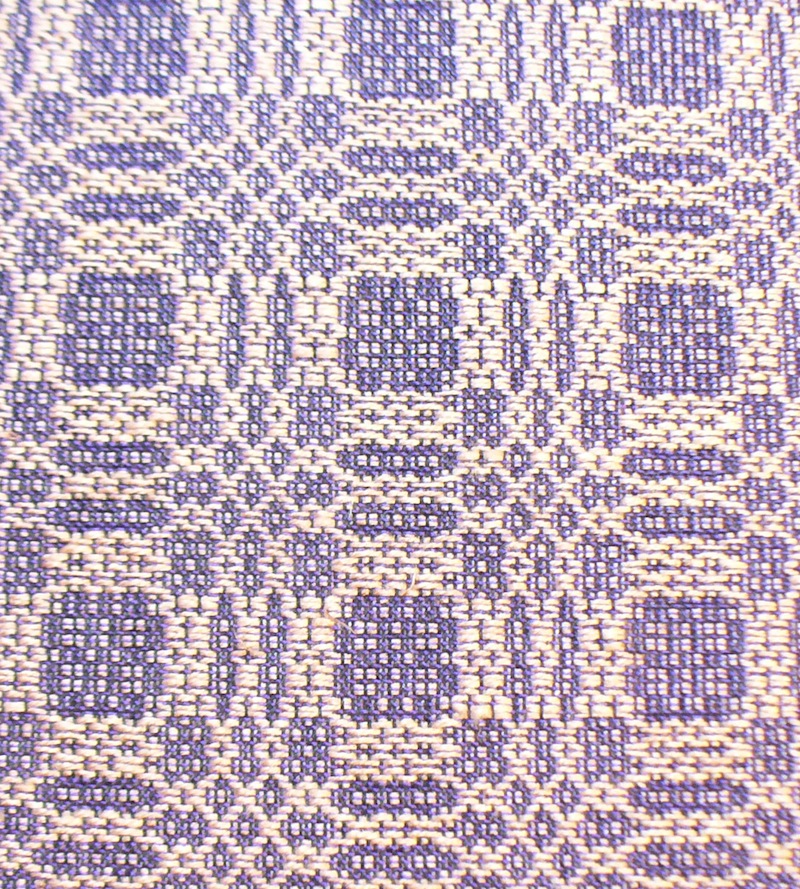

When I got into the woods at Amherst College, there were lots of interesting maple seeds and fallen tree-flowers on the path, so I picked up a few especially striking ones to photograph when I got home. At the moment I am very interested in the combination of bright yellow-greens and various shades of pink and maroon that are happening all over the place in small emerging leaves, flowering trees, and maple seeds. How do such bright colors blend so harmoniously? Are there optimal ratios? Which combinations do I like the best? Could I weave something with the same colors and achieve anything like the same effect? Here are some photos. The ones in bright sun I took the other day. The yellow inflorescences are from some kind of oak.

At one point I was noisily engaged in my own thoughts, making up a silly song that went like this: Don’t plant your flax in a hayfield/’cuz a hayfield is full of grass/no matter what you do/there are roots through and through/so don’t plant your flax in a hayfield. My songs are notoriously dumb, but I was mightily entertained by myself, and not paying much attention to the woods around me. But then I saw another maple seed bundle with a greater ratio of yellow to pink, and stopped to pick it up. At that moment, the noise in my head stopped, too, and my focus shifted back to the woods. And suddenly I heard a wood thrush! You can listen to lots of different recordings of wood thrush songs at the Macaulay Library archives.

At one point I was noisily engaged in my own thoughts, making up a silly song that went like this: Don’t plant your flax in a hayfield/’cuz a hayfield is full of grass/no matter what you do/there are roots through and through/so don’t plant your flax in a hayfield. My songs are notoriously dumb, but I was mightily entertained by myself, and not paying much attention to the woods around me. But then I saw another maple seed bundle with a greater ratio of yellow to pink, and stopped to pick it up. At that moment, the noise in my head stopped, too, and my focus shifted back to the woods. And suddenly I heard a wood thrush! You can listen to lots of different recordings of wood thrush songs at the Macaulay Library archives.

The wood thrush has the most beautiful voice I have ever heard. It evokes intense longing and utter contentment at the same time. Bliss. I love wood thrush season, and am always happy when they come back and sad when they leave.

My wood thrush backstory goes like this. Several years ago I started hearing this beautiful flute-like bird at the garden in the evenings. I began to listen for it while I was there, and look forward to hearing it. It felt affirming, reassuring, companionable…. but I could never see the bird that was singing because the song always came from deep in the woods. There are good resources for birdsong identification on line, but you have to know what a bird looks like to narrow down your search. So, the identity of my bird remained a mystery for several years. I began hearing it other places, too, including right by our apartment complex, especially early in the morning and around sunset.

One spring day maybe three years ago, I was sitting outside at the school where I worked, supervising kids playing outdoors. Amazingly, I heard my bird! So I peered over at the edge of the playground, next to the woods at the Larch Hill conservation area. And lo and behold, there was my bird singing away on a branch right at the edge of the woods. I moved closer and got a good look at it. It was a rich reddish-brown, about the size of a robin, with a white-and-black spotted breast and big feet. I found photos, descriptions, and recordings of its song on the Cornell University ornithology website, and at last identified my mystery bird.

A few months ago, as I was trying to think of a name for my new little weaving business, I decided to name it after the wood thrush.

There are a few reasons that wood thrushes appeal to me as a personal symbol of the ethics and aesthetics of fiber. I am very invested in locally grown and harvested fibers and dyes. I work hard to learn as much as possible about growing and using locally available fiber and dye plants, and to incorporate them into my work. I aspire to expand the range of fibers and dyes that are available to folks around here. But only certain materials can be obtained or produced in Massachusetts. One very useful fiber in particular, cotton, needs a much hotter, longer growing season than we can offer. But there are good, sustainable cotton projects going on further south, including an organic cotton industry in Texas, and naturally colored cottons in Peru. These projects need to be supported. The evils of conventionally raised cotton would take a whole other post to enumerate, but a good place to start, if you want to read about it, is Stephen Yafa’s Big Cotton and Cotton.

Despite my fibershed ideal, I decided I would need to include far-away fibers in my fiber-diet. Here’s where the wood thrush comes in. Wood thrushes migrate to Central America in the winter, and only come up to New England in the summertime. So, that span of distance, from Massachusetts to Panama at least (if not as far as Peru), is linked together by my bird. Wood thrushes go where the good stuff is, while it’s in season, and that’s one way to think about fibers, too.

Here are some other wood thrush lessons I have learned. Their song is very beautiful, but it’s pretty quiet and they stick to the woods. To hear it, you have to spend time outdoors and be attentive to the world around you. Understanding where fiber raw materials come from, and how inseparable their growth and processing are from every other element of our environment, requires similar attention and observation. The wood thrush is not a flashy bird. In fact it’s sort of subtle and even conservative, like much of my weaving tends to be. Wood thrush populations are in decline due to a variety of factors including habitat loss and acid rain. Sustainable land management and reducing pollution are crucial to their survival, and to the survival of us all.

So, I was ecstatic to hear that the wood thrushes are back.