OK, yes, the title is just an excuse to use a pun. In reality, once they were dry, the madder roots I harvested were not very heavy at all. But they did prompt me to do quite a bit of thinking and math about the yield of this “crop”.

In my last post I shared an image of four trays of roots, rinsed off and set up to dry on Saturday March 30th. Here’s a refresher. I love how they glisten and glow:

On Sunday March 31st I dug up three more trays just like them.

When they were freshly harvested, and before I rinsed them, the roots weighed just over 15 lb. I weighed them again after I rinsed them, thinking that the loss of soil weight would give a more accurate measurement. But instead, the added water weight increased the overall weight, which didn’t really help me figure out how heavy the roots were by themselves. So, I’m sticking with 15 lb. for this math.

Over the next couple weeks the trays sat in the apartment, outdoors, and in the van, depending on the weather. By Thursday April 18th they were dry and crispy. Plus, I was on April vacation and had time to deal with them.

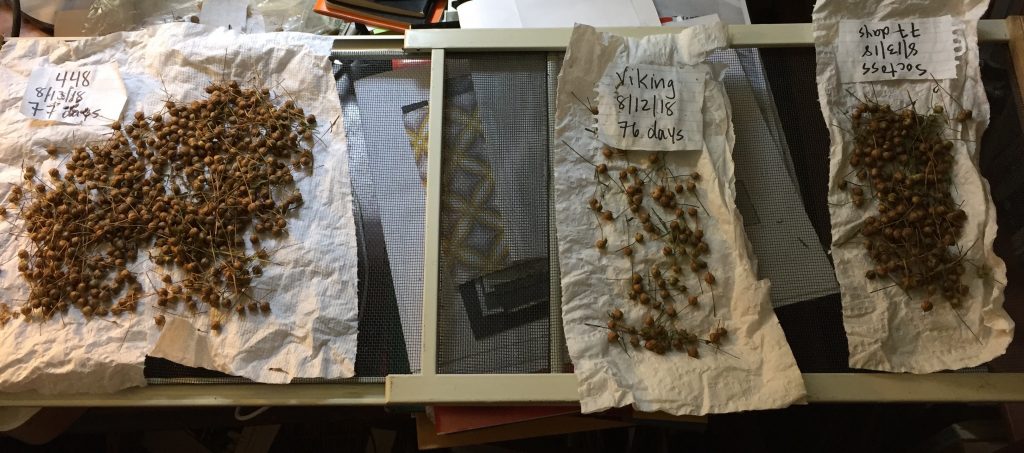

Here are some photos of the trays before I broke up the roots. There were seven trays altogether, but I figured four images is enough to get the idea.

Here are some close-ups. I took a ridiculous number of close-up photos because the closer I looked, the more amazing all the intricate tangles, textures, and colors were. Matthew characterized them fondly as “dusty sticks” and we agreed that happily examining dusty sticks is pretty typical of the way I like to spend my free time. So, here are some images of dusty sticks for your enjoyment:

In this photo below, you can see that my rinsing method wasn’t very thorough. There’s a clump of gritty soil lodged in the center of a curly twist of root. The pale straw-looking pieces are above-ground stalks:

In the photo below I’m interested in the dried skin that’s flaking off. It would be good to understand more about what’s happening there.

I like how the broken end in the root in this photo below looks like a mouth. The maw of madder.

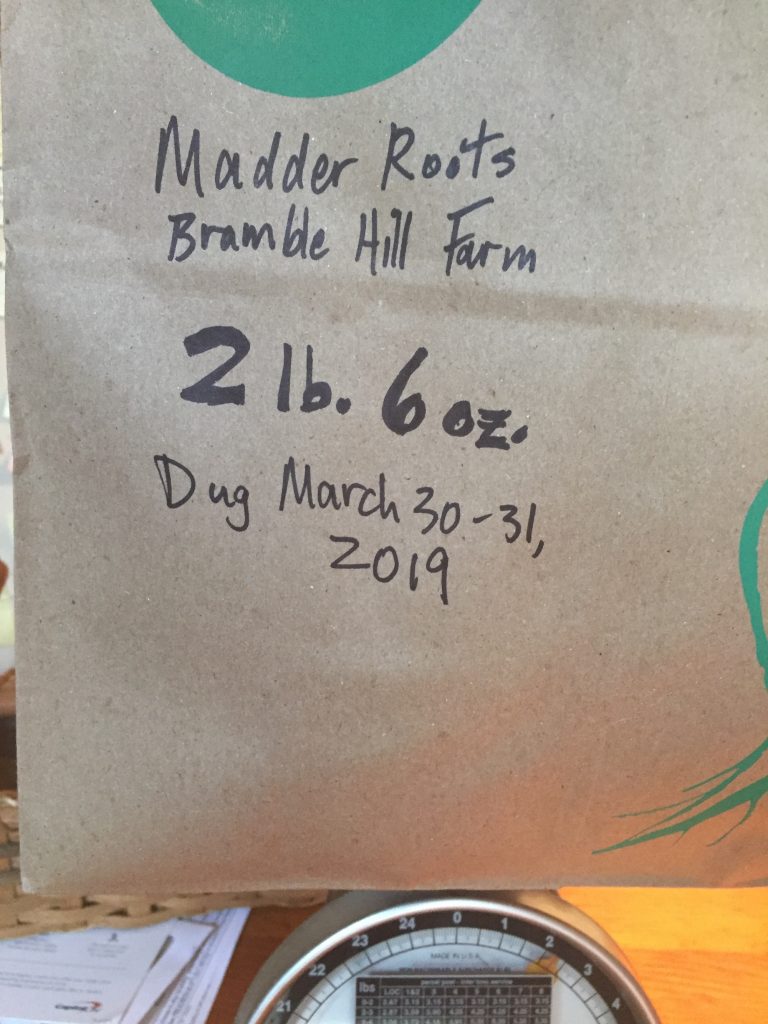

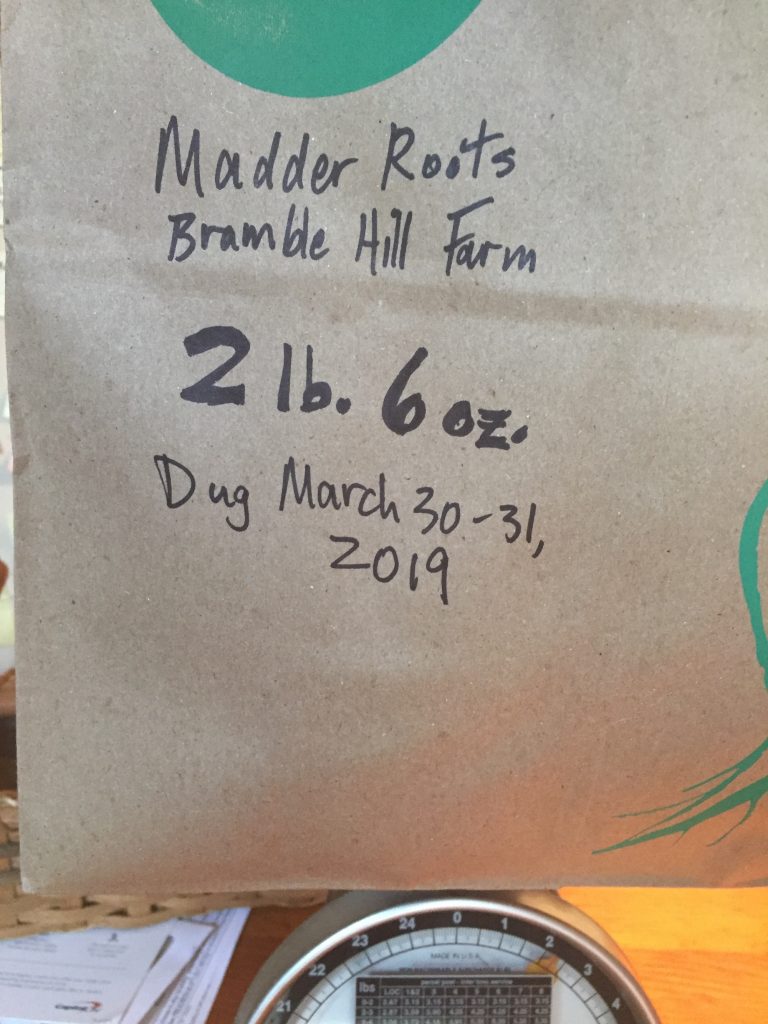

The total weight of dried snapped-up roots was only 2 lb. 6 oz (or 38 oz).

Here is the inside of the bag:

If my math is right, that’s approximately an 84% loss in weight. I ended up with about 15% of what I started with.

This surprised me, and made me wonder what the overall yield from the whole plot might be. The area I dug up that weekend was 115 square feet. This works out to about .33 ounces of dried roots per square foot. (38 ÷ 115 = .330 and to double-check, 115 x .33 = 37.95).

The remaining area that I haven’t dug up yet is 25 square feet, which means I could get 8 more ounces from that section (25 x .33 = 8.25). Which means the yield from the whole plot would be 46 ounces, or 2 lb. 14 oz. That’s almost 3 lb. if we’re rounding up. So, 140 square feet can yield just below 3 lb. of dried roots. Which doesn’t seem very productive to me, especially because you have to wait three years to harvest them, theoretically.

However, since I don’t really have anything to compare it to, I don’t really have a basis for judging whether .33 oz per square foot is a good yield or a bad yield. I decided I’d better do some reading. This is my first foray into this question, so I may come up with different and better information in the near future.

This article from a book on Google Books called A-Z vol. 4 supplement, written by Andrew Ure and Robert Hunt, published in 1878 by Longmans, Green, and Company, reports on page 160: “The quantity of fresh roots obtained in France from one arpent of ground (of 48,000 square feet) varies from 4,000 to 6,000 pounds.” The authors cite other units of measurement in other countries (units like morgens and cwts) but I didn’t have the patience to find out how to translate them to things I understand. So, let’s stick with France for now.

If 48,000 square feet yields 4,000 lb. of fresh roots, one square foot would be .0833 lb. or 1.33 oz.

Using my 15% figure for the dry weight, that would be .995 oz. of dried roots per square foot for the low range of the harvest. If 48,000 square feet yields 6,000 lb. fresh roots, that would be .125 lb. per square foot fresh, or 2 oz. and .3 oz. dried. Ha! Maybe my yield is actually as good as a French madder farmer in the 1870s! Phew, that’s a relief.

If you’re checking my math and you find it’s nutty and wrong, please email me.

Madder roots are currently on sale for $21.95/lb at Aurora Silks, $19.78/lb. at Dharma Trading, $40/lb (sold by the ounce) from Long Ridge Farm, and $28 for 500g at Botanical Colors (just to name a few vendors that I could check on line quickly this afternoon). So, that means every three years a madder bed filling 140 square feet of garden space could grow somewhere between $60 and $120 worth of roots.

I think I’ll stop there for now.